Most Popular Products

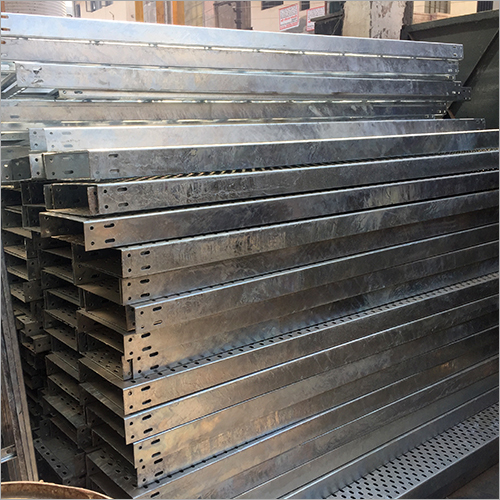

GI Earthing Strip

Price 70-85 INR/ Kilograms

MOQ : 1000 Kilograms

GI Earthing Strip Specification

- Mounting Type

- Surface mount

- Humidity %

- up to 95% RH non-condensing

- Efficiency

- High electrical and grounding efficiency

- Insulation Material

- Bare (non-insulated)

- Operating Temperature

- -10C to +80C

- Feature

- High conductivity, corrosion resistant, durable

- Surface Finish

- Galvanized finish

- Connector Type

- Cable lug or direct clamp

- Shape

- Flat / Rectangular Strip

- Product Type

- GI Earthing Strip

- Application

- Earthing systems in electrical installations, industrial, and commercial applications

- Protection Level

- Corrosion-resistant

- Frequency (MHz)

- 50-60 Hz

- Rated Voltage

- up to 440 V

- Color

- Silver / Metallic Grey

- Dimension (L*W*H)

- As per requirement (commonly 25mm x 3mm, 40mm x 6mm, or customized)

- Weight

- Approximately 7-15 kg (varies with size and length)

- Size

- Available in various sizes (width 25mm to 75mm; thickness 3mm to 10mm)

- Phase

- Single Phase

- Connection Type

- Bolted or welded connections

- No Of Poles

- Single

- Material

- Galvanized Iron (GI)

- Galvanization Thickness

- Minimum 80 microns

- Service Life

- More than 10 years (in normal conditions)

- Minimum Order Quantity

- 50 meters

- Tensile Strength

- 350-450 MPa

- Corrosion Resistance Test

- Passed (Salt spray test as per IS standards)

- Packaging Type

- Bundled or coil-packed

GI Earthing Strip Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 2-3 Days

About GI Earthing Strip

GI Earthing Strip is a conventional method for providing earthing to the various area like residential, industrial, commercial, etc. It is usually used for providing a stable platform for operation of sensitive equipment. Our professionals use galvanized iron for manufacturing GI Earthing Strip. We offer this at highly pocket- friendly prices.

Exceptional Corrosion Resistance

Each GI Earthing Strip undergoes a salt spray test as per IS standards, ensuring the highest level of corrosion resistance. The minimum galvanization thickness of 80 microns acts as a protective layer, making these strips highly suitable for long-term service even in humid environments, with a rated lifespan exceeding 10 years under normal conditions.

Customizable and Versatile Solutions

Available in various sizes and thicknesses, the GI Earthing Strip can be tailored to fit specific project requirements. Whether for an industrial complex or a commercial facility, common dimensions such as 25mm 3mm and 40mm 6mm are offered, with the flexibility for customized measurements to ensure optimal compatibility and effectiveness for every application.

Reliable Performance for Electrical Safety

Designed for efficient electrical grounding, these flat rectangular strips provide high conductivity and durable protection with a robust tensile strength of 350450 MPa. They support rated voltage up to 440 V and are compatible with single-phase applications, making them indispensable in enhancing electrical safety across various installations.

FAQs of GI Earthing Strip:

Q: How is the GI Earthing Strip installed in grounding systems?

A: The GI Earthing Strip is installed by either bolting or welding onto the grounding network. It can be surface-mounted using cable lugs or direct clamps, ensuring secure and efficient connections within electrical, industrial, or commercial earthing systems.Q: What benefits does the thick galvanization layer offer for GI Earthing Strips?

A: A minimum of 80 microns galvanization greatly enhances the strips corrosion resistance, ensuring a long service life of over 10 years under standard conditions. This protective zinc coating also minimizes maintenance requirements and supports reliable performance even in humid or outdoor environments.Q: When should I consider using GI Earthing Strips over other grounding materials?

A: GI Earthing Strips are best used when high durability, cost-effectiveness, and excellent corrosion resistance are requiredparticularly in electrical installations, industrial plants, or commercial complexes where reliable grounding is critical for safety and equipment protection.Q: Where are GI Earthing Strips commonly applied?

A: These strips are utilized in a range of settings including building electrical installations, industrial facilities, telecommunications infrastructure, and commercial projects where effective earthing is necessary to ensure safety and prevent electrical faults.Q: What sizes and packaging options are available for GI Earthing Strips?

A: GI Earthing Strips are available in widths from 25mm to 75mm and thicknesses from 3mm to 10mm. Packaging can be in bundled or coil-packed forms, with a minimum order quantity of 50 meters to suit various project scales.Q: How is the corrosion resistance of the strip assured?

A: The strips pass a salt spray test according to IS standards, confirming their robust corrosion resistance. The galvanized finish further protects the material from environmental factors, supporting longevity in diverse conditions.Q: What is the process for customizing strip dimensions to suit project needs?

A: Customers can specify their required length, width, and thickness within the available range when placing an order. The manufacturer will produce the strips as per those dimensions, ensuring precise fit and functionality for each unique application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ADITYA STEEL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry